工業(yè)閥門作為流體控制系統(tǒng)的關(guān)鍵部件,根據(jù)其結(jié)構(gòu)特點和功能特性可分為多種類型,每種閥門都具有獨特的性能優(yōu)勢和應(yīng)用場景。以下是對各類閥門的詳細技術(shù)分析:

Industrial valves, as key components of fluid control systems, can be classified into various types based on their structural and functional characteristics, each with unique performance advantages and application scenarios. The following is a detailed technical analysis of various types of valves:

一、球閥技術(shù)特性分析

1、 Analysis of Technical Characteristics of Ball Valve

球閥憑借其獨特的球形啟閉件設(shè)計,在各類閥門中展現(xiàn)出最優(yōu)異的流體動力學(xué)性能。其核心部件是一個帶有通孔的精密球體,通過90度旋轉(zhuǎn)實現(xiàn)流道的啟閉控制。從流體力學(xué)角度看,即便是縮徑設(shè)計的球閥,其流阻系數(shù)也僅為0.05-0.1,遠低于其他類型閥門。直角回轉(zhuǎn)二通球閥作為過程控制領(lǐng)域的標(biāo)準(zhǔn)配置,采用兩通二位式設(shè)計,具有啟閉迅速(僅需1/4轉(zhuǎn))、密封可靠(金屬/軟密封可選)和操作扭矩小等特點。現(xiàn)代球閥已發(fā)展出全通徑、V型調(diào)節(jié)、三通分流等多種變體,廣泛應(yīng)用于石油天然氣長輸管線(Class600以上)、化工裝置(耐腐蝕材質(zhì))等嚴(yán)苛工況,特別適合需要快速切斷的緊急隔離系統(tǒng)。

Ball valves, with their unique spherical opening and closing design, exhibit the best fluid dynamics performance among various types of valves. The core component is a precision sphere with a through-hole, which controls the opening and closing of the flow channel through a 90 degree rotation. From the perspective of fluid mechanics, even ball valves with reduced diameter designs have a flow resistance coefficient of only 0.05-0.1, far lower than other types of valves. As a standard configuration in the field of process control, the right angle rotary two-way ball valve adopts a two-way two position design, which has the characteristics of rapid opening and closing (only 1/4 turn required), reliable sealing (metal/soft seal optional), and low operating torque. Modern ball valves have developed various variants such as full bore, V-shaped regulation, three-way diversion, etc., and are widely used in harsh working conditions such as long-distance oil and gas pipelines (Class 600 or above), chemical plants (corrosion-resistant materials), etc. They are particularly suitable for emergency isolation systems that require rapid shutdown.

二、旋塞閥結(jié)構(gòu)特點解析

2、 Analysis of the structural characteristics of plug valves

旋塞閥采用圓柱形或圓錐形閥塞作為核心控制元件,其流道可根據(jù)需要設(shè)計為矩形、梯形等異形結(jié)構(gòu)。該類型閥門具有三大顯著優(yōu)勢:1)直通式流道設(shè)計使流阻系數(shù)保持在0.1-0.3區(qū)間;2)90度快速啟閉特性(動作時間<1秒);3)多端口設(shè)計(三通、四通)可實現(xiàn)復(fù)雜流體分配。特殊的錐面配合結(jié)構(gòu)使其能夠處理含固體顆粒(粒徑≤3mm)的漿料介質(zhì),在采礦、污水處理等行業(yè)表現(xiàn)突出。現(xiàn)代旋塞閥采用PTFE襯里或金屬硬密封技術(shù),最高可耐受450℃高溫和Class600壓力等級,成為苛刻工況下流體控制的可靠選擇。

Plug valves use cylindrical or conical valve plugs as the core control components, and their flow channels can be designed as rectangular, trapezoidal, or other irregular structures as needed. This type of valve has three significant advantages: 1) The straight through flow channel design keeps the flow resistance coefficient in the range of 0.1-0.3; 2) 90 degree fast opening and closing characteristics (action time<1 second); 3) Multi port design (three-way, four-way) can achieve complex fluid distribution. The special conical fitting structure enables it to handle slurry media containing solid particles (particle size ≤ 3mm), which has outstanding performance in industries such as mining and wastewater treatment. Modern plug valves use PTFE lining or metal hard sealing technology, which can withstand up to 450 ℃ high temperature and Class 600 pressure rating, making them a reliable choice for fluid control under harsh working conditions.

三、蝶閥流量控制機理

3、 Flow control mechanism of butterfly valve

蝶閥通過圓盤狀閥瓣在流道中的角度變化實現(xiàn)流量調(diào)節(jié),其核心優(yōu)勢體現(xiàn)在:1)緊湊型結(jié)構(gòu)使安裝空間需求減少60%;2)大流量特性(Cv值可達10000以上);3)低壓降設(shè)計(全開時流阻系數(shù)僅0.2-0.6)。雙偏心、三偏心結(jié)構(gòu)的出現(xiàn)使蝶閥的密封性能大幅提升,最高可達到ANSI Class VI泄漏標(biāo)準(zhǔn)。在DN300以上大口徑管路中,蝶閥的性價比優(yōu)勢尤為明顯,已成為給排水系統(tǒng)(工作壓力≤1.6MPa)、通風(fēng)系統(tǒng)(溫度≤120℃)等中低壓場合的首選控制設(shè)備。智能型電動蝶閥更集成了流量特性修正功能,可實現(xiàn)精確的過程控制。

Butterfly valves achieve flow regulation by changing the angle of the disc-shaped valve disc in the flow channel, and their core advantages are reflected in: 1) the compact structure reduces installation space requirements by 60%; 2) High flow characteristics (Cv value can reach over 10000); 3) Low pressure drop design (flow resistance coefficient is only 0.2-0.6 when fully open). The emergence of double eccentric and triple eccentric structures has greatly improved the sealing performance of butterfly valves, reaching up to ANSI Class VI leakage standards. In large-diameter pipelines above DN300, butterfly valves have a particularly obvious cost-effectiveness advantage and have become the preferred control equipment for medium and low pressure applications such as water supply and drainage systems (working pressure ≤ 1.6MPa) and ventilation systems (temperature ≤ 120 ℃). The intelligent electric butterfly valve integrates flow characteristic correction function, which can achieve precise process control.

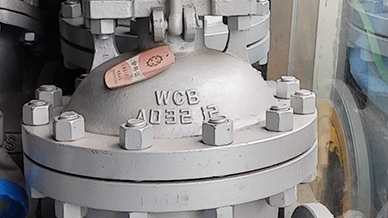

四、閘閥密封技術(shù)演進

4、 Evolution of Gate Valve Sealing Technology

閘閥采用垂直于流體的閘板運動方式,其技術(shù)發(fā)展主要體現(xiàn)在密封結(jié)構(gòu)上:1)楔式閘板通過錐面配合實現(xiàn)金屬硬密封(角度通常為5°-10°);2)平行式閘板采用雙閘板+彈簧預(yù)緊結(jié)構(gòu);3)刀型閘閥專門針對含纖維介質(zhì)設(shè)計。雖然閘閥不適用于節(jié)流控制(易產(chǎn)生氣蝕),但其全開時流道完全暢通(流阻系數(shù)僅0.1-0.2)的特點,使其在蒸汽系統(tǒng)(工作溫度≤425℃)、原油管線(Class150-2500)等需要全通徑的場合仍不可替代。近年來開發(fā)的壓力自密封閘閥,利用介質(zhì)壓力增強密封比壓,顯著提升了高壓工況下的可靠性。

Gate valves adopt a vertical movement of the gate plate perpendicular to the fluid, and their technological development is mainly reflected in the sealing structure: 1) Wedge gate plates achieve metal hard sealing through cone fitting (usually at an angle of 5 ° -10 °); 2) The parallel gate adopts a double gate and spring pre tensioning structure; 3) Knife gate valves are specifically designed for media containing fibers. Although gate valves are not suitable for throttling control (prone to gas corrosion), their characteristic of completely unobstructed flow channels when fully opened (with a flow resistance coefficient of only 0.1-0.2) makes them irreplaceable in steam systems (working temperature ≤ 425 ℃), crude oil pipelines (Class 150-2500), and other situations that require full bore. In recent years, pressure self sealing gate valves have been developed that utilize medium pressure to enhance sealing pressure, significantly improving reliability under high-pressure conditions.

五、截止閥精密控制能力

5、 Precision control capability of globe valve

截止閥通過閥瓣與閥座的線接觸密封實現(xiàn)精確流量調(diào)節(jié),其技術(shù)特點包括:1)閥瓣行程與流量呈線性關(guān)系,調(diào)節(jié)特性優(yōu)良;2)多回轉(zhuǎn)操作(通常需要3-5圈全關(guān))實現(xiàn)精細控制;3)閥座可更換設(shè)計延長使用壽命。角式截止閥采用90度流道轉(zhuǎn)向,特別適合管道拐角處安裝。在發(fā)電廠給水系統(tǒng)(工作壓力≤32MPa)、化工過程控制(泄漏等級≤ANSIV)等需要精確調(diào)節(jié)的場合,截止閥展現(xiàn)出不可替代的優(yōu)勢。三通截止閥通過特殊流道設(shè)計,可實現(xiàn)兩種介質(zhì)的精確配比混合,混合精度可達±2%。

The globe valve achieves precise flow regulation through the line contact sealing between the valve disc and the valve seat. Its technical features include: 1) the valve disc stroke is linearly related to the flow rate, and the regulation characteristics are excellent; 2) Multi turn operation (usually requiring 3-5 turns to fully close) to achieve fine control; 3) The valve seat can be replaced to extend its service life. The angle type globe valve adopts a 90 degree flow channel turning, which is particularly suitable for installation at pipeline corners. In power plant water supply systems (working pressure ≤ 32MPa), chemical process control (leakage level ≤ ANSIV) and other situations that require precise adjustment, globe valves demonstrate irreplaceable advantages. The three-way globe valve can achieve precise mixing of two media through a special flow channel design, with a mixing accuracy of ± 2%.

六、針閥微調(diào)技術(shù)剖析

6、 Analysis of Needle Valve Fine Adjustment Technology

針閥作為截止閥的特殊變體,其核心技術(shù)在于:1)錐形針狀閥瓣(錐角通常為30°-60°)與微小孔口(直徑1-5mm)的精密配合;2)細牙螺紋傳動(螺距0.5-1mm)實現(xiàn)微米級行程控制;3)高硬度材料配對(如碳化鎢/藍寶石)確保長期穩(wěn)定性。這些特性使針閥能夠?qū)崿F(xiàn)0.1-5L/min的精確流量控制,在分析儀器(液相色譜)、實驗裝置(壓力調(diào)節(jié))等微小流量場合具有絕對優(yōu)勢。超高壓針閥(工作壓力≤10000psi)采用自增強密封結(jié)構(gòu),成為石油勘探、高壓化工等特殊領(lǐng)域的必備設(shè)備。

As a special variant of the globe valve, the core technology of the needle valve lies in: 1) the precise fit between the conical needle valve disc (cone angle usually 30 ° -60 °) and the small orifice (diameter 1-5mm); 2) Fine thread transmission (pitch 0.5-1mm) achieves micrometer level stroke control; 3) High hardness material pairing (such as tungsten carbide/sapphire) ensures long-term stability. These characteristics enable the needle valve to achieve precise flow control of 0.1-5L/min, which has an absolute advantage in small flow situations such as analytical instruments (liquid chromatography) and experimental devices (pressure regulation). The ultra-high pressure needle valve (working pressure ≤ 10000psi) adopts a self reinforced sealing structure and has become an essential equipment in special fields such as petroleum exploration and high-pressure chemical engineering.

七、電磁閥響應(yīng)特性分析

7、 Analysis of Response Characteristics of Electromagnetic Valve

電磁閥通過電磁力直接驅(qū)動閥芯,其技術(shù)核心在于:1)直動式結(jié)構(gòu)(DN≤6mm)實現(xiàn)毫秒級響應(yīng)(≤20ms);2)先導(dǎo)式設(shè)計(DN6-50mm)利用介質(zhì)壓力輔助動作;3)脈沖保持技術(shù)降低功耗90%。受限磁路效率,電磁閥通常設(shè)計為小流量通路(Cv值0.01-3.0),但其無可比擬的快速響應(yīng)特性,使其在自動化生產(chǎn)線(動作頻率≤10Hz)、安全聯(lián)鎖系統(tǒng)(響應(yīng)時間≤50ms)等需要快速切斷的場合不可或缺。防爆電磁閥采用澆封型結(jié)構(gòu),可應(yīng)用于Zone1危險區(qū)域。

The electromagnetic valve directly drives the valve core through electromagnetic force, and its technical core lies in: 1) the direct acting structure (DN ≤ 6mm) to achieve millisecond level response (≤ 20ms); 2) Pilot design (DN6-50mm) utilizes medium pressure to assist in movement; 3) Pulse holding technology reduces power consumption by 90%. Due to limited magnetic circuit efficiency, solenoid valves are usually designed as small flow paths (Cv values of 0.01-3.0), but their unparalleled fast response characteristics make them indispensable in situations such as automated production lines (operating frequency ≤ 10Hz) and safety interlock systems (response time ≤ 50ms) that require quick shut-off. The explosion-proof solenoid valve adopts a sealed structure and can be applied to Zone 1 hazardous areas.

八、角座閥氣動執(zhí)行技術(shù)

8、 Pneumatic Execution Technology for Angle Seat Valves

角座閥集成了氣動執(zhí)行機構(gòu)與角形閥體,其創(chuàng)新設(shè)計包括:1)45°傾斜閥座實現(xiàn)流線型通道(流阻系數(shù)0.3-0.8);2)活塞式執(zhí)行器(工作壓力0.2-0.8MPa)提供高啟閉力;3)快拆式閥芯便于維護。相比傳統(tǒng)球閥,角座閥具有三大優(yōu)勢:1)動作速度提升50%(全行程時間≤1秒);2)流量系數(shù)提高30%;3)使用壽命延長至百萬次以上。這些特性使其在啤酒灌裝(CIP清洗)、制藥設(shè)備(無菌要求)等需要頻繁動作的自動化場合廣受歡迎。氣動角座閥與電磁閥組合使用,可構(gòu)建高效的氣動控制系統(tǒng)。

The angle seat valve integrates a pneumatic actuator and an angle valve body, and its innovative design includes: 1) a 45 ° inclined valve seat to achieve a streamlined channel (flow resistance coefficient 0.3-0.8); 2) Piston actuator (working pressure 0.2-0.8MPa) provides high opening and closing force; 3) Quick detachable valve core is easy to maintain. Compared to traditional ball valves, angle seat valves have three major advantages: 1) a 50% increase in action speed (full stroke time ≤ 1 second); 2) Increase the flow coefficient by 30%; 3) The service life is extended to over a million times. These characteristics make it widely popular in automation scenarios that require frequent actions, such as beer filling (CIP cleaning) and pharmaceutical equipment (sterile requirements). The combination of pneumatic angle seat valve and solenoid valve can construct an efficient pneumatic control system.

各類閥門的技術(shù)經(jīng)濟比較表明,在實際工程選型中應(yīng)綜合考慮流體特性、壓力溫度、控制要求和安裝條件。現(xiàn)代流體控制系統(tǒng)趨向于采用組合方案,如主管路采用球閥保證低阻切斷,支路使用截止閥實現(xiàn)精確調(diào)節(jié),特殊工況配置旋塞閥處理顆粒介質(zhì),通過科學(xué)的閥門組合實現(xiàn)最優(yōu)的流體控制解決方案。隨著智能控制技術(shù)的發(fā)展,電動執(zhí)行器、定位器、物聯(lián)網(wǎng)模塊的集成應(yīng)用,使傳統(tǒng)閥門正加速向智能化方向演進。

The technical and economic comparison of various types of valves shows that in practical engineering selection, fluid characteristics, pressure and temperature, control requirements, and installation conditions should be comprehensively considered. Modern fluid control systems tend to adopt combination schemes, such as using ball valves to ensure low resistance cut-off in the main pipeline, using globe valves for precise adjustment in branch pipelines, configuring plug valves for handling granular media in special working conditions, and achieving optimal fluid control solutions through scientific valve combinations. With the development of intelligent control technology, the integrated application of electric actuators, positioners, and IoT modules is accelerating the evolution of traditional valves towards intelligence.

本文由良工閥門友情奉獻.更多有關(guān)的知識請點擊:http://www.szgotta.com.cn真誠的態(tài)度.為您提供為全面的服務(wù).更多有關(guān)的知識我們將會陸續(xù)向大家奉獻.敬請期待.

This article is a friendly contribution from Lianggong Valve For more information, please click: http://www.szgotta.com.cn Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

企業(yè)公告:

企業(yè)公告: